Steam Tender Conversion and Ultra-Detailing in “O” Scale…Virginian Coal Tender #803 to VGN Aux Tank #A27

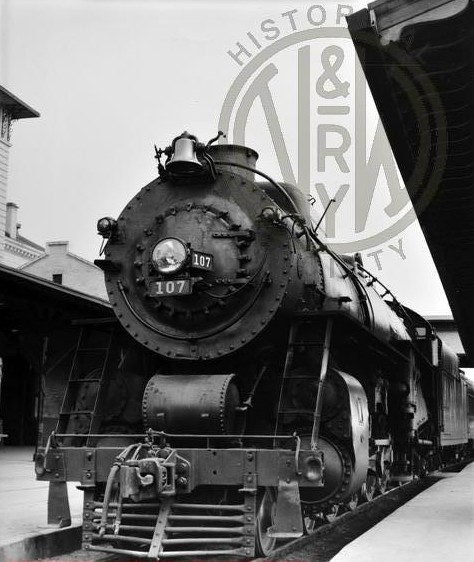

The Prototype…

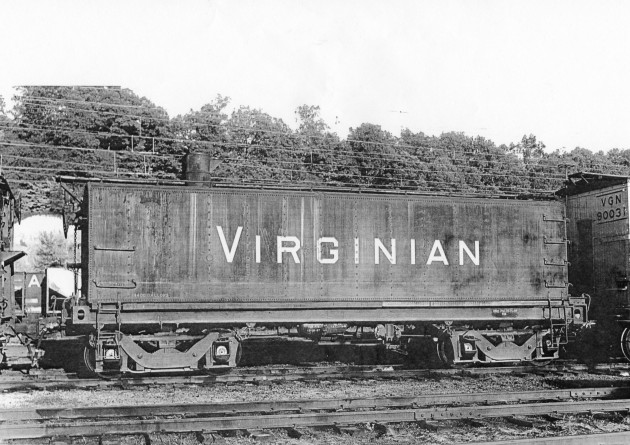

VGN Aux Tank built from one of the 14,400 gallon AB/AD tenders…

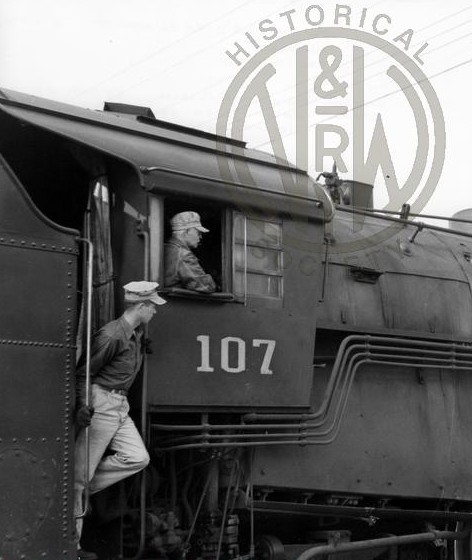

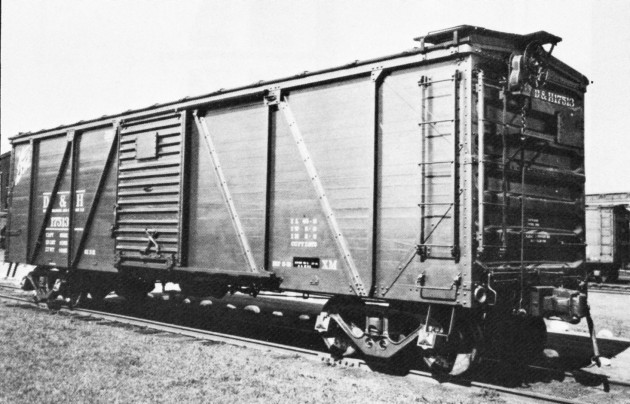

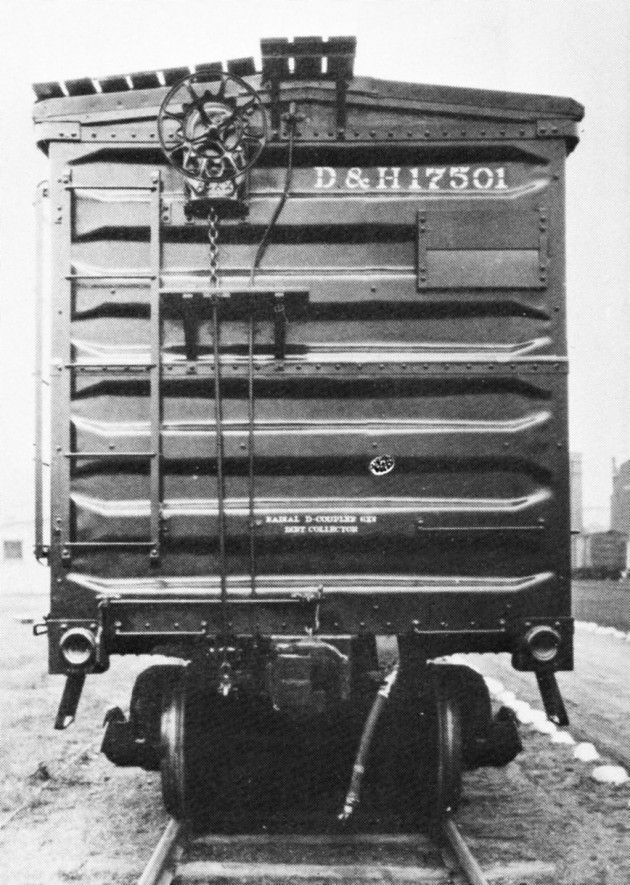

Although few in number, the Virginian Railway was well know for their massive articulated steam locomotives, particularly their AB/AD Class 2-8-8-2’s and AE Class 2-10-10-2’s. In the late 1940’s and early ’50’s, with even more new electric locos making inroads, the VGN scrapped some of those big steamers and salvaged the coal tenders from seven of them. The tenders that were saved were sent to the Virginian’s Princeton Shops, where they were converted to water-carrying Aux Tank cars.

Effectively, the coalboards were removed and sheetmetal covers were fabricated to seal off the top and the end of the bunker. The cistern ring and hatch was narrowed and extended, a freight car style AB brake system was installed, as well as freight car running boards, hand grabs, backup light and safety appliances. The front end beam was modified to accept a coupler instead of a drawbar.

The intent of the Company in building these was to couple them to the rear of existing steamers to double their onboard water supply, thereby reducing or eliminating a number of water stops. Other railroads in the east built aux tanks (aux water cars) too, most notably the N&W and Reading. These VGN cars were also used in MOW and other service.

Of the seven cars built, five were 14,400 gallon tanks taken from the AB/AD 2-8-8-2’s and two were 13,000 gallon tanks taken from the AE 2-10-10-2’s. The first five were rebuilt into aux tanks after WWII and the last two were rebuilt in the early 1950’s.

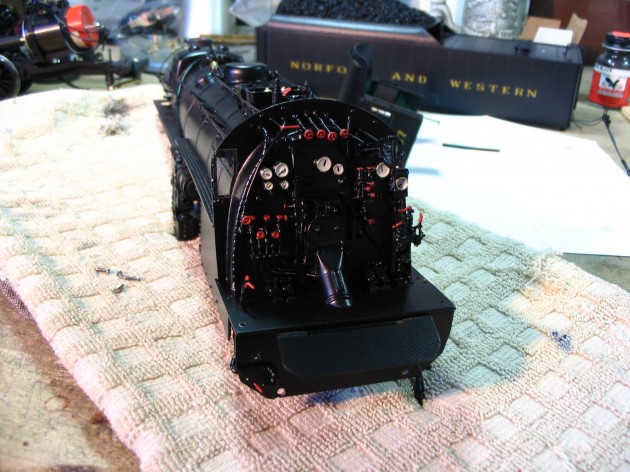

The Model…as delivered

For this commission, the client shipped me a complete, pristine model of one of the AE tanks from the recent run of the Sunset/3rd Rail VGN 2-10-10-2’s. The client had planned this conversion prior to the Sunset models being completed, and ordered just a tender for this purpose.

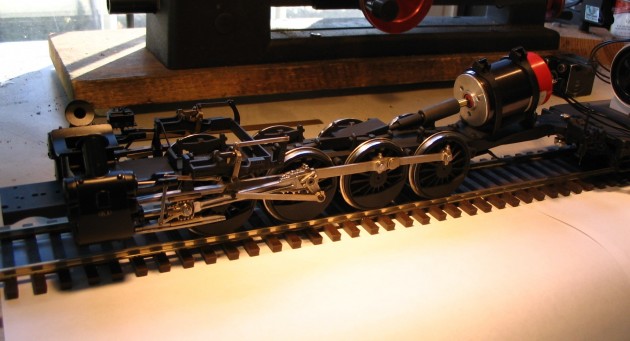

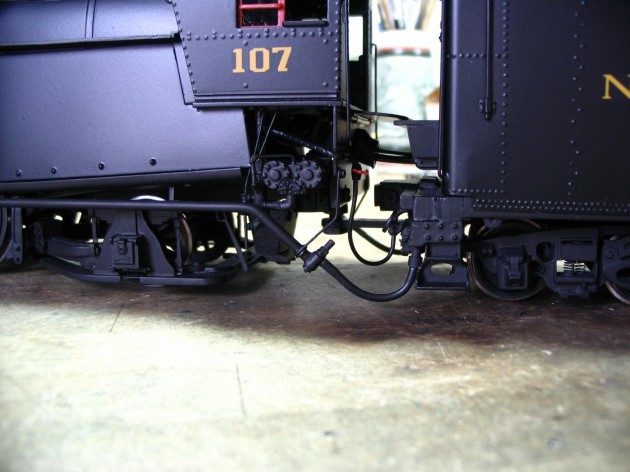

Here’s a few shots of the brand new tender as delivered to me…

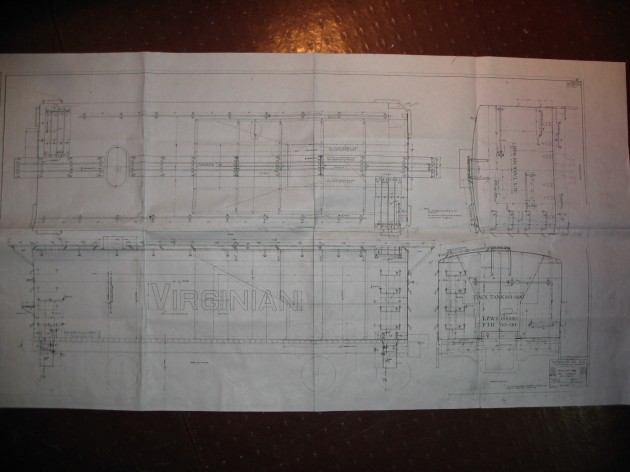

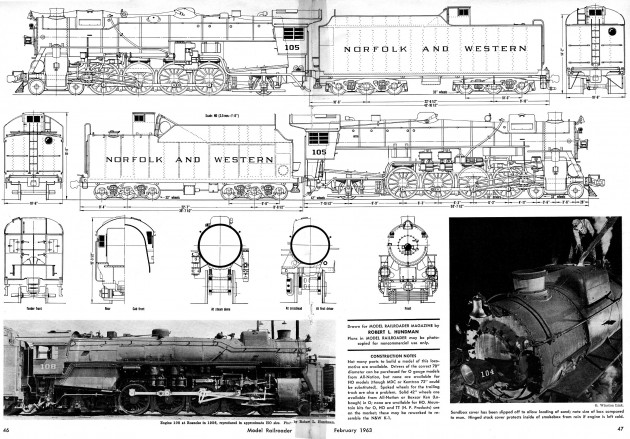

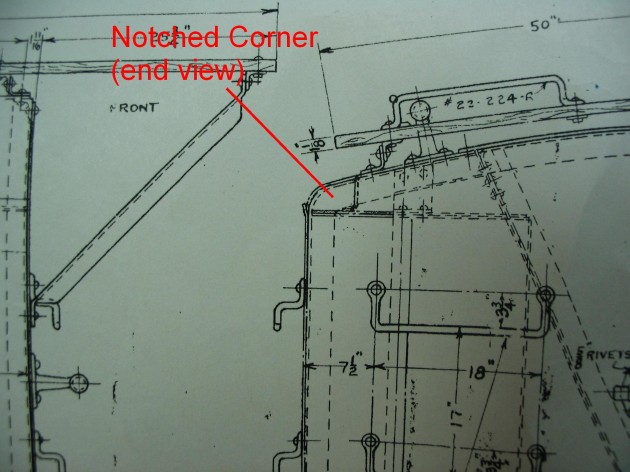

As was done at Princeton, the goal here was to convert the stock coal tender into the modified aux tank. Fortunately, the client was able to supply me with a copy of the actual 3/8″ = 1′ erecting drawing used by the VGN to make these modifications. Here is an image of that print.

The Conversion…

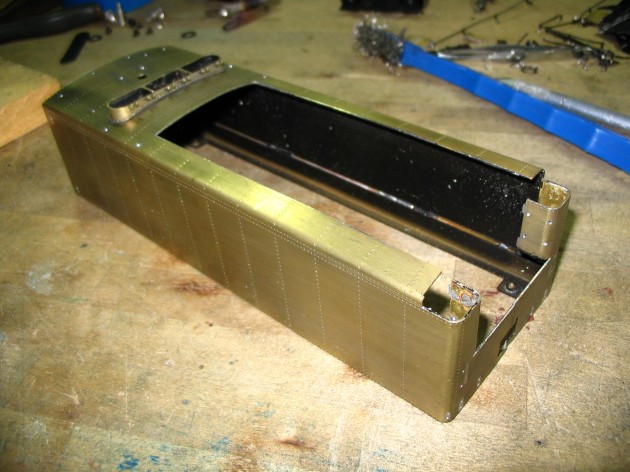

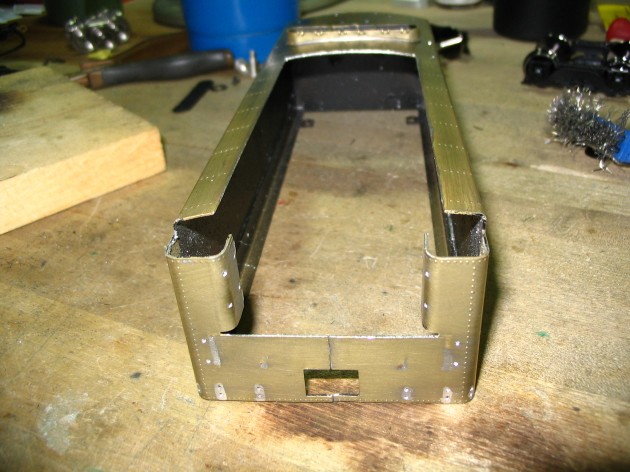

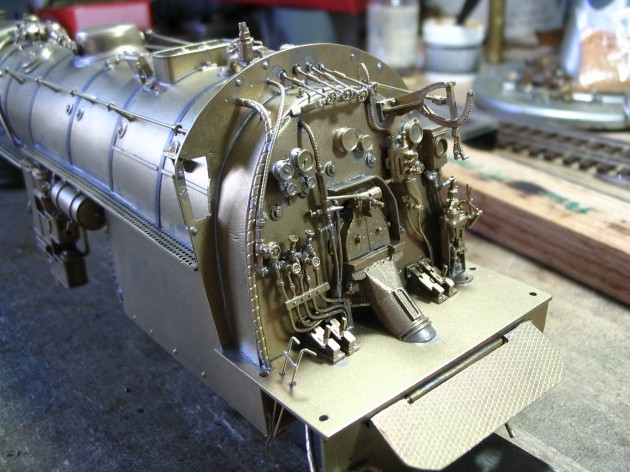

The rebuilding process to create an aux tank from this stock tender was EXTENSIVE. And even though the original paint and lettering was pretty good, it could not be saved and had to be stripped. Here’s a few shots of the model after all the details, un-needed parts and paint have been removed.

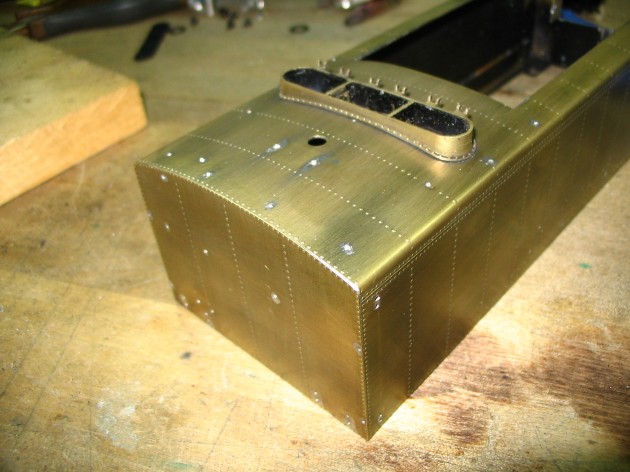

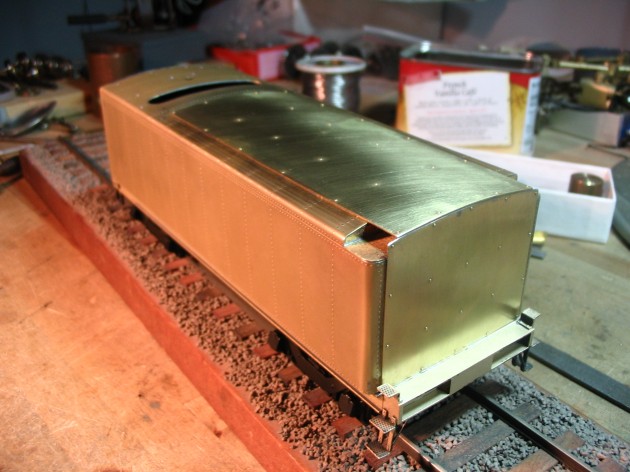

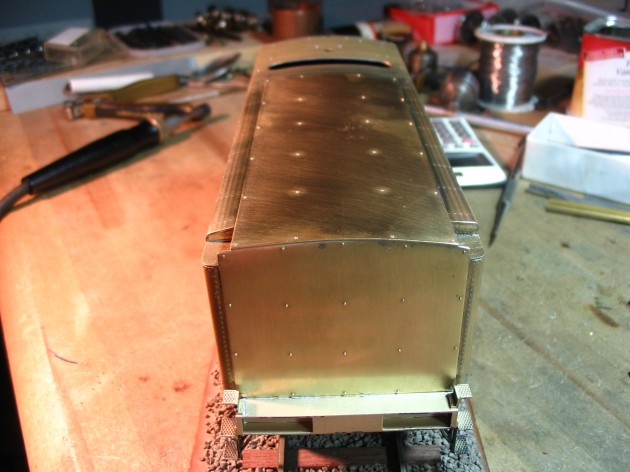

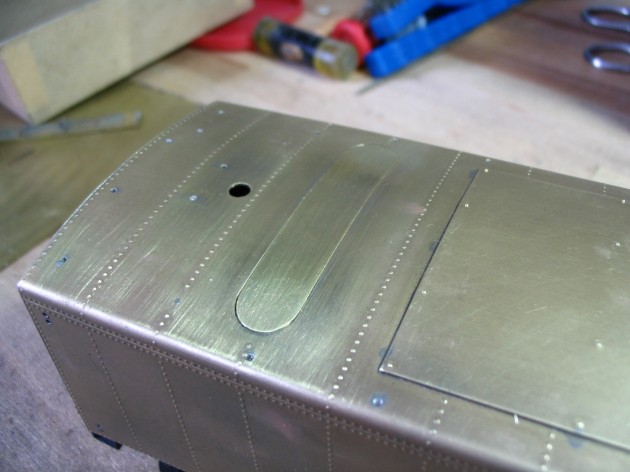

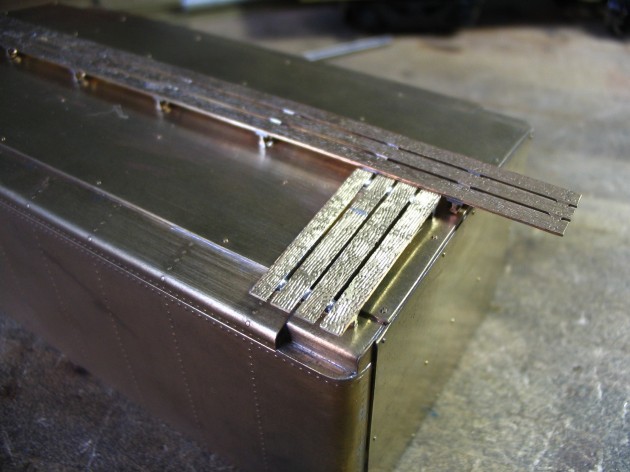

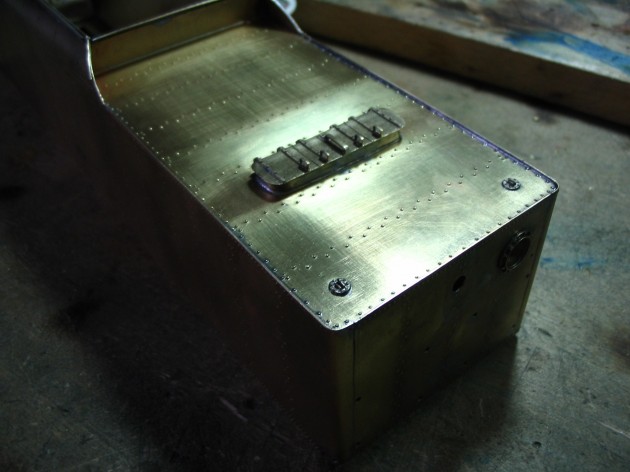

As with the prototype, new sheetmetal covers (with rivet detail) to cover the top and end of the coal bunker were fabricated and installed.

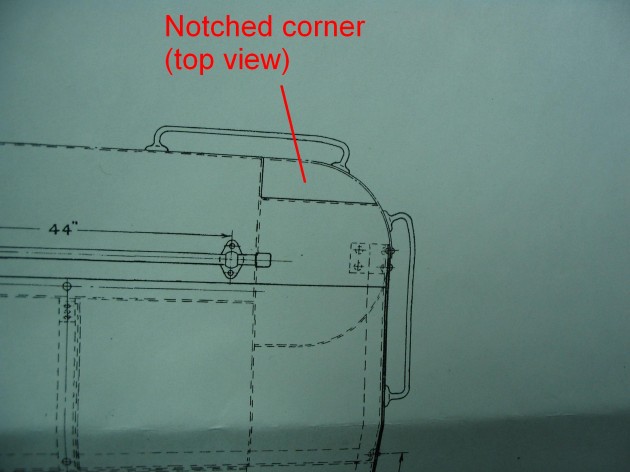

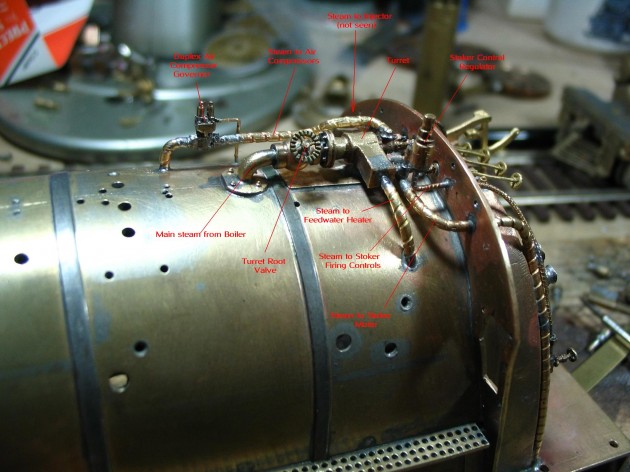

Accurate end fillets then had to be fabricated to fill in the openings between the new end and top sheets. There was some confusion about just how these were to be rendered, since no good closeup images of the corner treatments exists. Looking at the Company print, in two out of thee views (end and top) it would appear that there is a 18″ long x 4 1/2″ wide notched step at the joint. That made sense, as the Princeton Shop would have had limited metal forming capabilities, and creating a complex, compound curved section of steel sheet to perfectly fill in that space with no step or notch (just for the sake of asthetics) would have been way too much work.

Here are some closeups of the print that shows the notched fillet…

Here’s a close up of the completed engineer’s side fillet installed, maintaining the correct length, width and depth of the notch (as per the print).

Princeton reduced the width of the cistern deck water hatch on these tanks, so following suit I filled in the old opening with several layers of brass, to accommodate a smaller filler.

After soldering in the new filler sections, the top of the tender was filed smooth to blend all the seams together. The eched rivets were filed off too, but will be restored prior to painting.

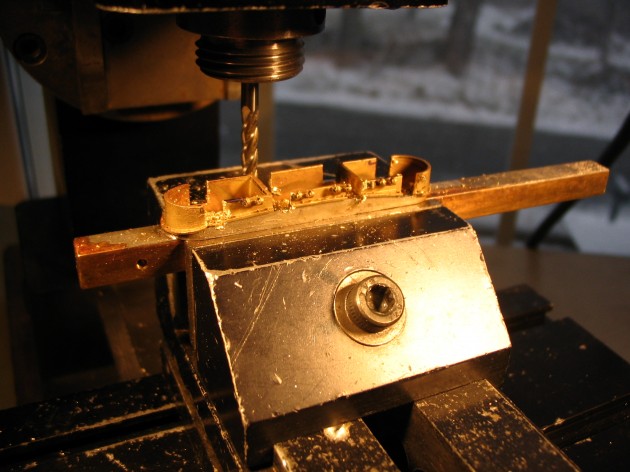

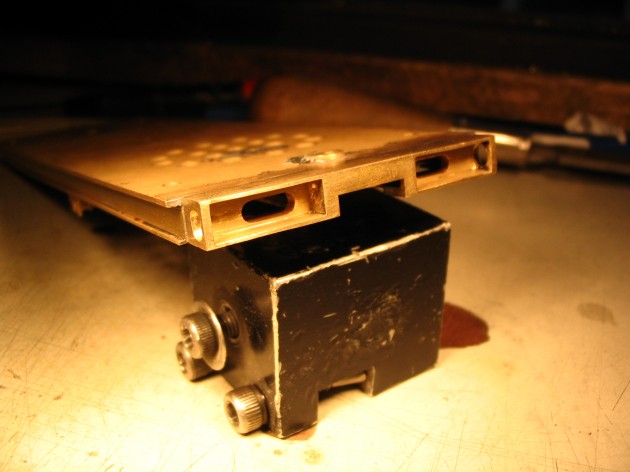

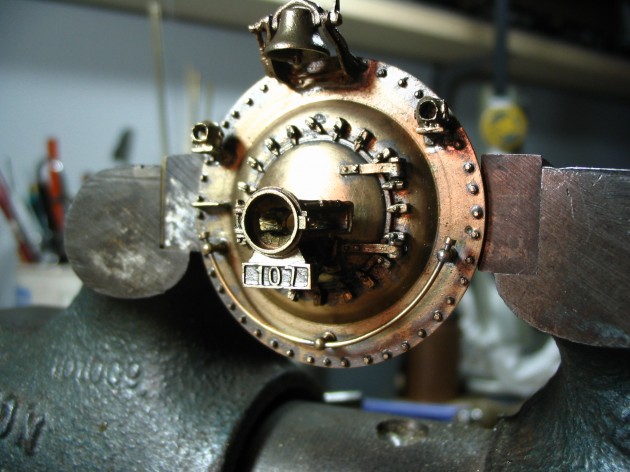

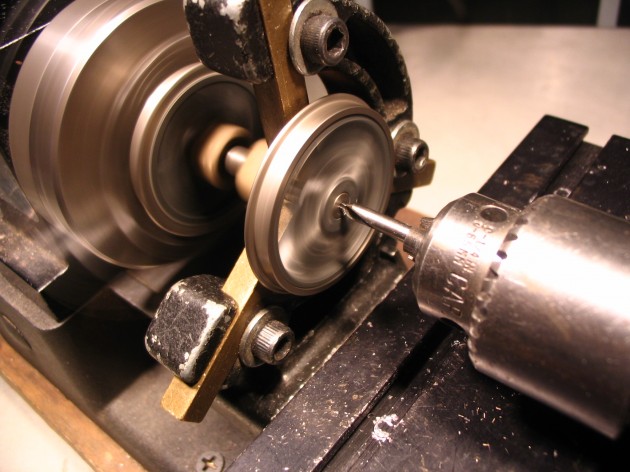

Once the old opening was filled and the new one cut in, it was time to turn my attention to modifying the water hatch ring and lid. The ring casting was fixtured into the milling machine, and two segments near the middle were removed.

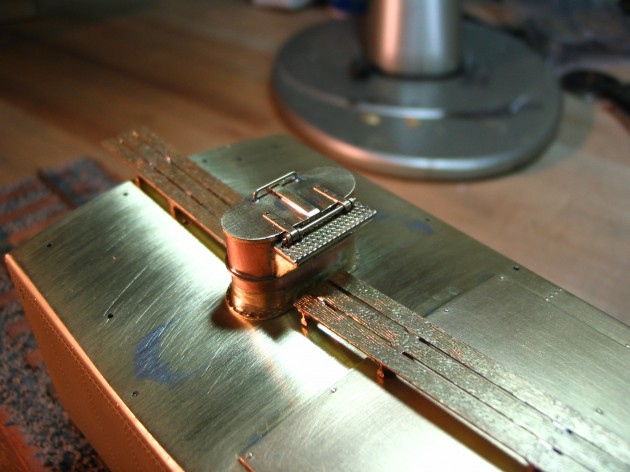

The remaining center section and two small curved end sections were then fixtured, and joined together with solder. A new, extended center colum, lid and platform was fabricated and joined to the smaller base ring to complete the assembly.

Here’s the completed hatch assy. installed in the new cistern deck opening (with the running boards mocked up).

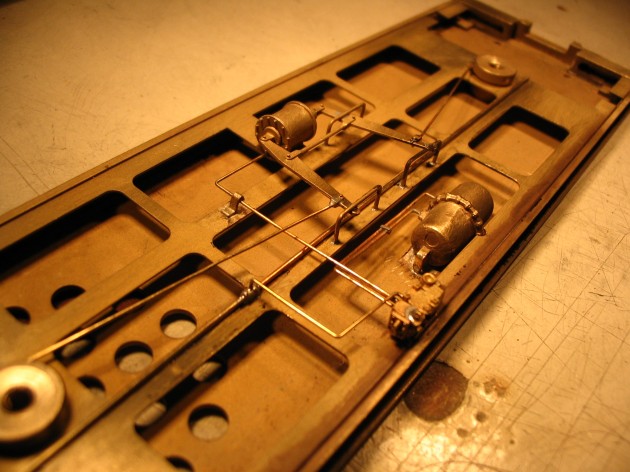

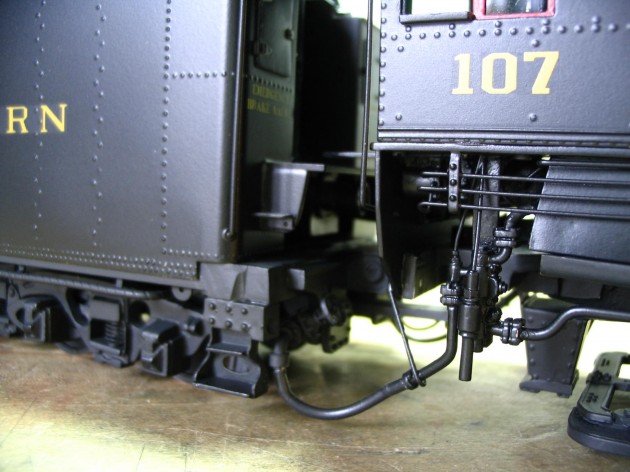

Using the prototype as a guide for component location, a full AB brake system was made up and installed…

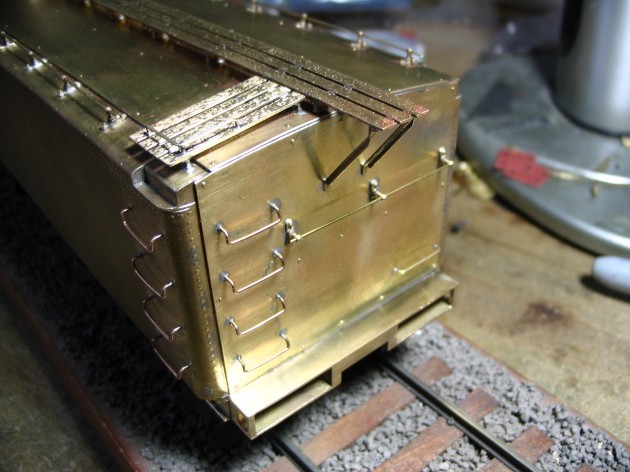

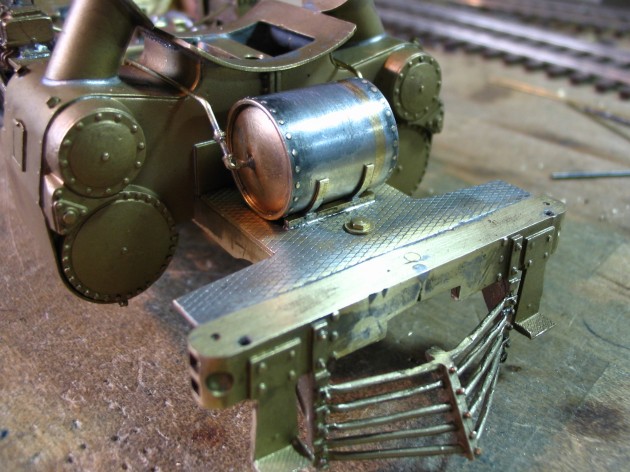

New front end beam was fabricated per the print and attached to the deck…

Running boards and end platforms were installed…

Next up…drop grabs, end grabs, deck railings, and roof walk end supports. All parts were custom fabricated…

Yard steps and rungs were individually fabricated from brass strip…

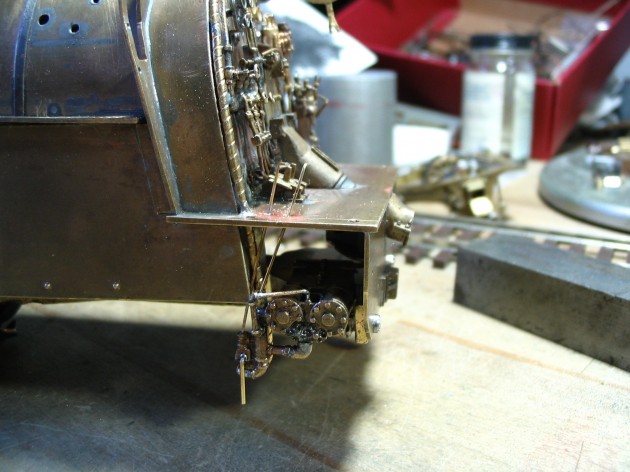

Ajax brake box, brake chain and brake step were added, along with coupler cut levers, back up light and tank stays, completing the fabrication, and making the model ready for paint/lettering.

The Completed Model…

3/4 View “B” end…

Side view…

Top View “B” end…

“B” end…

“A” end…

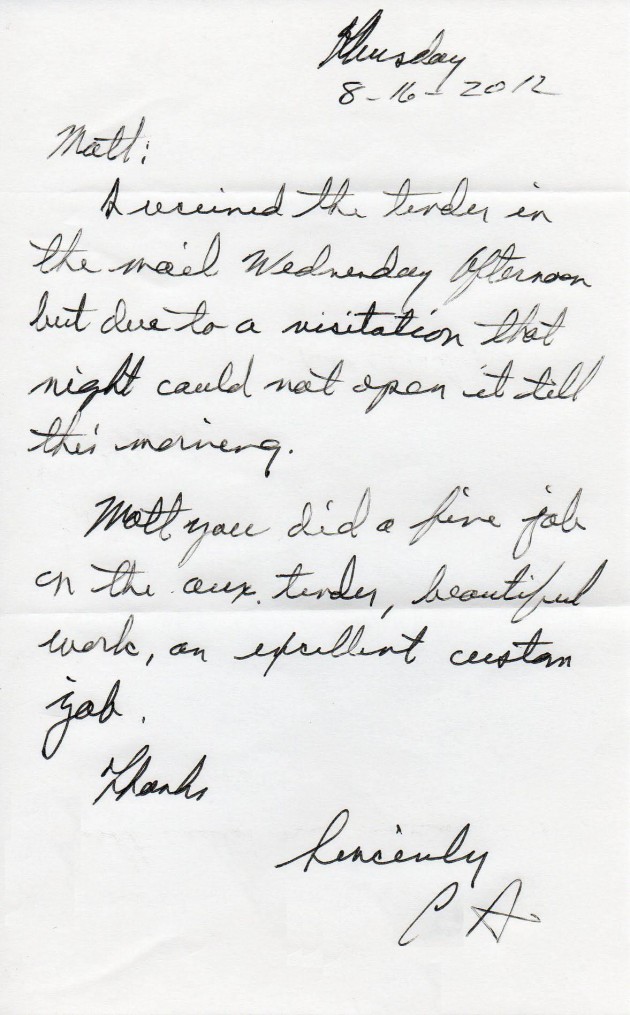

After I shipped the finished model to the client, I received this letter in the mail…