Steam Locomotive Ultra-Detailing in “O” Scale…PRR I1sa #4390

Even though I do a LOT of scratch building and brass bashing for my own railroad, in support of both my D&H and Erie fetishes (you gotta roll your own if your’re going to model steam for either of those roads), I also regularly take on commissions for other clients from both the U.S. and overseas.

This past spring (2010) I took on a box-stock US Hobbies PRR I1s project. The client, a physician from New England, wanted this loco as accurately detailed as was humanly possible. Using detailed images from the period for this loco, I took this generic Penn I1s and totally reworked it into ultra-detailed PRR I1sa #4390, as she appeared in 1953.

Ultra-detailed backhead and boiler of I1sa #4390 (click on image to enlarge, and then click again)

Backhead of #4390 after initial detailing…

Partial cab interior and boiler viewed from Fireman’s side (note the addition of the reach rods from the starter valve and the injector on both the steam supply and water dump sides of the valve). This is how the Fireman controlled these components without leaving the cab…

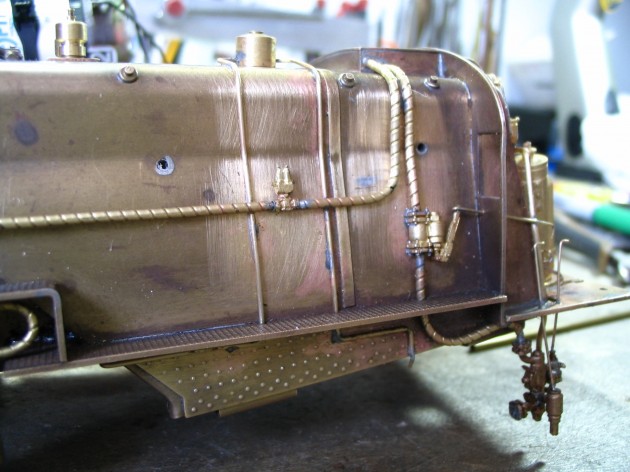

Broadside of Fireman’s side of the boiler, with details for this section of the boiler nearing completion…

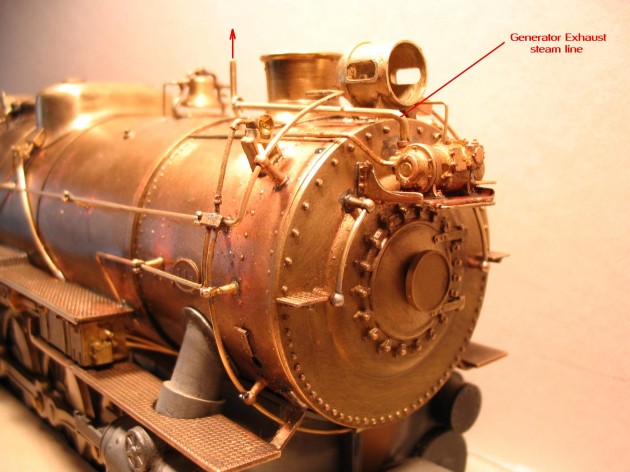

Fireman’s side front end after having received the “WWII Beauty Treatment”…

Engineer’s side front end showing many additional details, including the Turbo-Generator exhaust steam pipe and standoff, that connects to the generator and exits along side the stack (an often overlooked detail)…

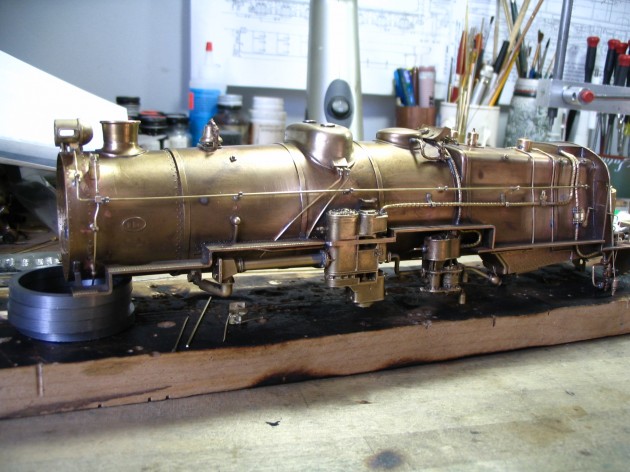

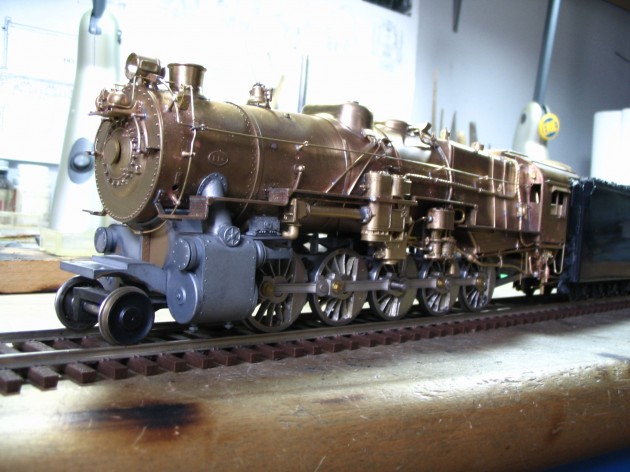

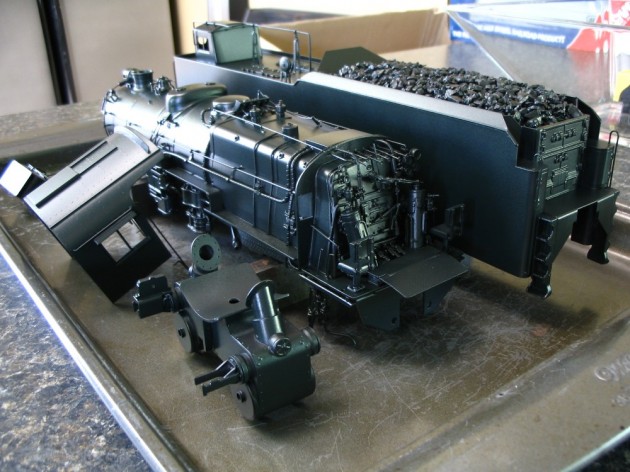

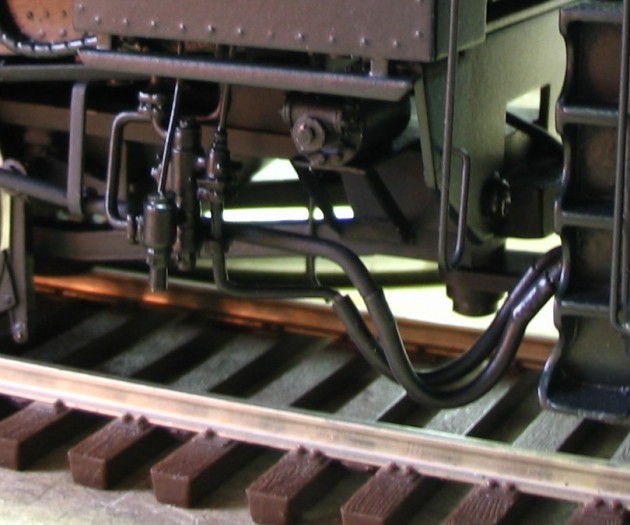

Boiler is regularly test-fit to the chassis during the detailing process, ensuring that proper running clearances are maintained between the new boiler details and all moving parts, i.e. drivers, rods, valve gear, etc…

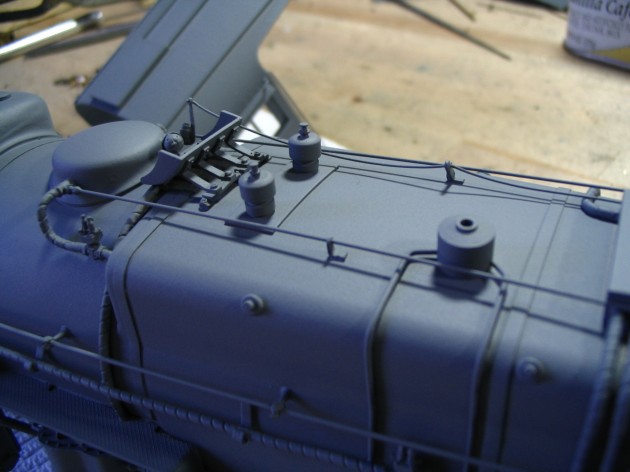

Belpaire topside details showing the addition of the two reach-rods and rod-guides that control component steam supply. The rods penetrate the front cab bulkhead, and end over the top of the crew’s head. Their red handles can be seen in the very first image in this section.

http://mattforsyth.com/wp-content/uploads/2010/08/I1sa-detail-023.jpg

The arching whistle chord and guides from the whistle’s accuating lever and back to the Engineer can also be seen. This chord is made from 0.005 brass wire that has been anealed, formed and re-hardend, which allows it to take on and maintain this shape.

Here are all the components cooling, having come fresh from the paint oven. All parts are baked at 175 degrees for three hours to cure and harden the paint. Paint for this model is ScaleCoat PRR Brunswick Green (DGLE). The paint is not applied directly to the primer coat, as it is too green from the bottle. Instead, after priming, the entire loco is first painted semi-flat black, and that coat is then baked. 48 hours later, the Brunswick green is applied. Doing this dramatically darkens the green top coat to a near-black. Later, after lettering and clear, matte top-coat, this near black color throws off green hues in both natural and artificial light, just as a fresh, PRR paint job would have done on the prototype.

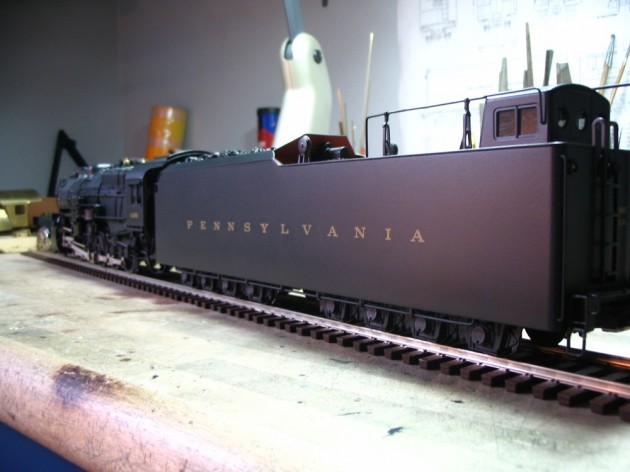

210-F-75b tender for #4390 nearing completion. It still lacks a tail light, marker jewels, and cab glass…

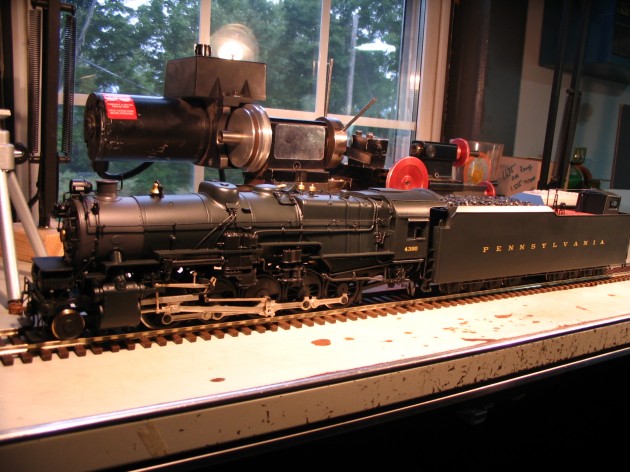

The completed I1sa #4390. Both the locomotive and tender were given a pristine, factory-level plus paint job and lettering. Per the customer’s request, no weathering was applied.

The completed I1sa #4390. Ready to ship to the customer…

Re-detailed with Post WWII front end…

Engineer’s side…

Fireman’s side…

Tender detail 3/4 view…

Water line hose connection detail to injector and Worthington BL4B feedwater heater…