Evolution of the 40′ Steam Era House Cars of the Delaware & Hudson

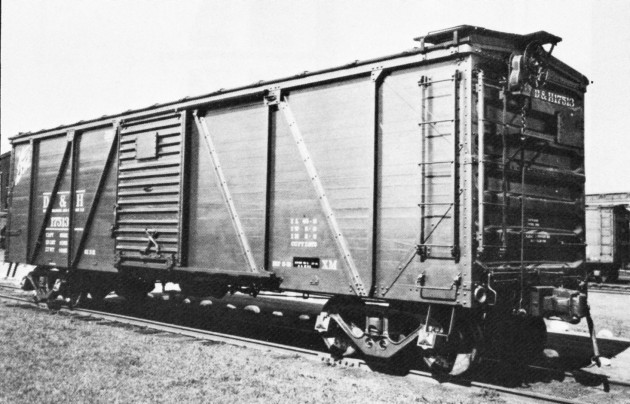

USRA Single Sheathed, 40 foot “Government” boxcar, built in 1919, series 17001-17500. This is #17225, as she appeared after her 1937 rebuilding, and wearing the new post 1950 D&H paint scheme. Note the Viking roof, that was a part of the upgrading process. Cars got either a Murphy Raised Panel roof, Climax Radial, or a Viking Ribbed. Number assignments as to the type of roof applied to which car were random. Inside height was 9′-0″. (image courtesy Steam Era Freight Cars)

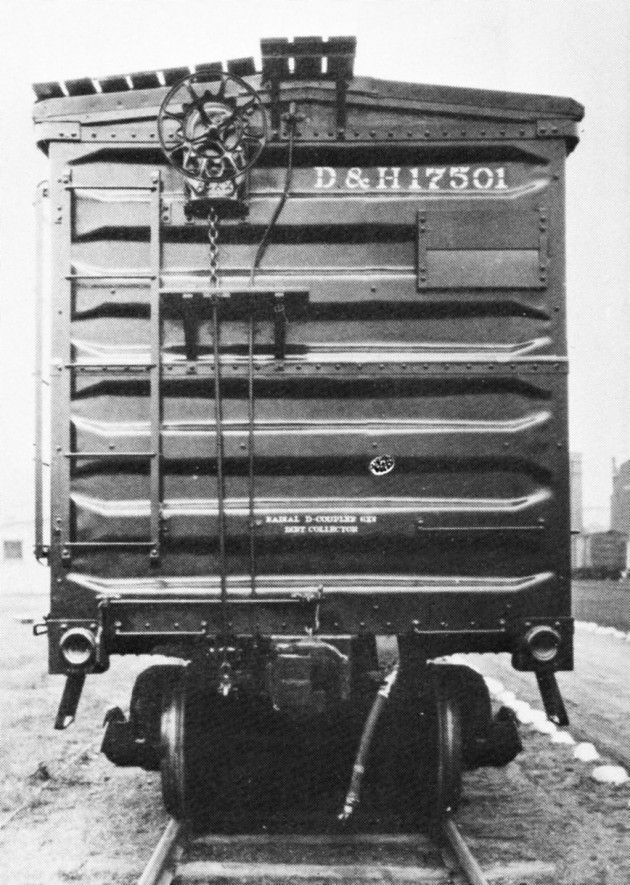

Green Island 17513, 3/4 builders (image courtesy R.P.I. D&H Collection)

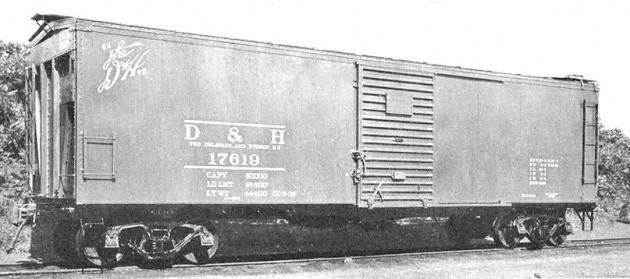

Green Island 17501 showing detail of reverse Hutchins end, builders (image courtesy R.P.I. D&H Collection)

(image courtesy Robert A. Lijestrand)

The ubiquitous “Green Island” single sheathed boxcar. Oneonta Shops built the bulk of the D&H’s rolling stock, but the Green Island shops built this batch. There were 100 cars in the group, #17501-17600, built 1931. These cars were built on a construction philosophy similar to that of the Fowler Patent and Candian Pacific 40′ “Dominion” cars. These featured “Z” channel bracing, reversed Hutchins ends, National B-1 trucks, Murphy Improved roof, and an 8′-7″ inside height.

Oneonta Shops “near” AAR ’32 Standard, 40′, all steel “semi-clone”, built 1930, series 17601-17625. This car series, although not a true clone, and equipped with a recessed “Z”-braced, steel end, was built following the ’32 AAR plan, that was published in late 1929. Often the AAR would publish their newest spec. in advance of acceptance, for the “Enlightnment of the RR Industry”. The actual spec. might not be ratified and made a legitmate standard by the committee-at-large for a year or more after initial publishing. Inside height was 9″-1″.

This could be considered a Company “Builder’s Photo” of the first of her kind. Again, this is a product of the D&H’s Green Island Shops, and shown at Oneonta. The car is #17626, and is an all-welded AAR ’32 Standard true “Clone”. The year is 1934, and 100 cars of this type, in this series were built, #17626-17725, between 1934 and 1937.

The car utilized internal ribs, with external steel sheathing welded to them from the inside. TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding did not exist at this time, so the bonds were made with the old fashioned Arc welding process. Unlike modern methods, Arc welding generates a tremendous amount of heat, and distributes it over a wide area. If you look closely, you’ll note the semi-uniform waves or “ripples” in the side sheathing; a permanent deformitity created by the extreme heat of the Arc. Inside height was 9′-4 1/2″.

The famous D&H 100 Years “Anthracite Circle” was not applied to the car when new, not becoming part of the D&H freight car paint scheme until the arrival of the Bethlehem Steel-built “Fishbelly” twin hoppers, starting in 1939. This car and her sisters received that herald begining in 1940.

(image courtesy Norm Buckhart/Protocraft.com)

Here’s another builder’s image of ’32 clone sister car #17721. The image above this one shows the very first car in the series, and this one shows almost the last; the final car in this group being #17725. When these cars were first starting to be built in 1934, the Murphy raised-panel roof was new on the freight car scene. The D&H, always on the cutting edge of new technology, quickly adoted this new roof for these builds. Looking at the eaves of this broadside, one can just make out the edges of the raised panels, visible between each roof rib.

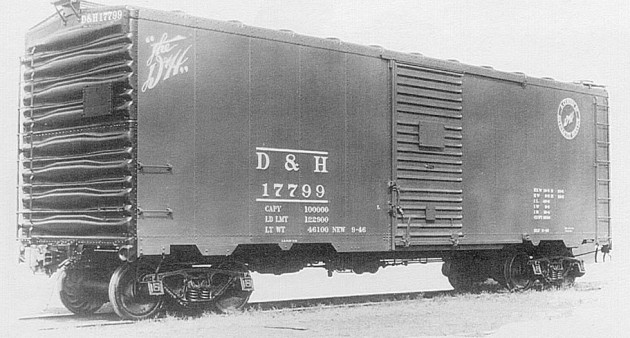

American Car & Foundry (ACF), AAR ’44 Standard, #17799, built 1946. Series #17726-17799. The last 25 of these cars #17775-17799 were equipped with auto parts racks by Oneonta Shops, so that they could carry new radiators from Ford Motor Company’s plant in Anderson, Indiana, to their assembly plant in Sommerville, MA. They remained in this dedicated service until the spring of 1956, at which time the racks were removed, and these cars were placed in regular interchange service with their sisters. All-welded construction, 4/4 improved Dreadnaught ends, Murphy Raised-panel roof. Car was painted all red with black ends only, when delivered new. 10′-4″ inside height.

The dedicated radiator service continued through 1956 and beyond, but in a different car. In that same year the D&H bought eleven (11), 50′ PRR double door X33’s. Oneonta Shops equipped these cars with racks, and these cars were then placed in that service.

Oneonta Shops #17889, built 1947-48, series 17800-17899. These cars were home-built to the AAR ’44 Std. spec. All-welded construction, with a unique 14 panel side, 3/4 Improved Dreadnaught ends, Murphy raised-panel roof, and 10′ inside height. This series of cars was one of the late-built types, that still retained the older 10′-0″ IH of the original ’37 Standard. Entire car painted red.

(not shown) Oneonta Shops-built, AAR ’44 Std. spec boxcars, series 17900-18049…

(image courtesy Jonathan Ferraro)

(image courtesy Robert A. Lijestrand)

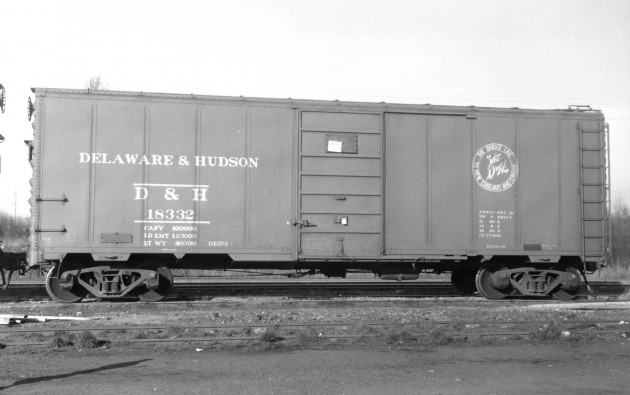

Oneonta Shops #18119, #18184, #18332 and #18368, built 1949, series 18100-18399. These cars were home-built to the AAR ’44 Std. spec. All-welded construction with double-welded, “flat side ribs”, 3/4 Improved Dreadnaught ends with added square top rib, Murphy diagonal-panel roof, 10′-6″ inside height. Of the 300 cars in this series, the first 200 were equipped with Youngstown doors, and last 100 with seven-panel Superior doors. Note the unsual, purpose-applied rivet patterns on the first three panels of #18368. Cars were painted all red.

Pullman Standard “PS-1″ # 18522, built 1950, series #18400-18899. 10′-6” inside height. Although built in 1950, and with only two year old Pullman-delivered paint in this 1952 view, note the conspicuous omission of the Company’s Anthracite Circle medallion. The Anthracite “100 Years” logo was adopted as a standard part of Company freight car lettering in 1939, but it is obvious that even though it was a standard part of the D&H Company paint, not all rolling stock got the complete treatment. This car is actually painted in the pre-1939 scheme, that did not sport the Anthracite Circle. Body of the car is red, with black car cement ends; the “traditional” Pullman Standard paint job of the era.

The first Bridge Line Circle medallion was adopted in 1951, with the delivery of the Bethlehem-built AAR Std. offset twin hoppers (the medallion was 41″ in diameter). The second order of Pullman Standard PS-1 boxcars also received it, but in a smaller 33″ version. (image courtesy Robert A. Lijestrand)

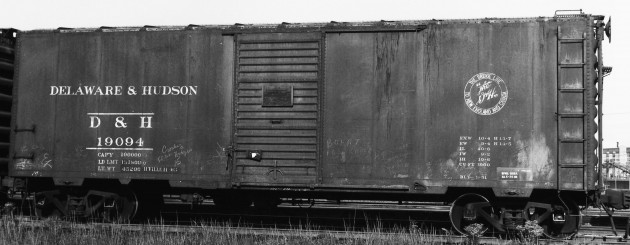

Here we see a member of the second order of Pullman Standard PS-1’s, series #18900-19399. Built March of 1951, this is the first of the D&H boxes to wear the newly devised paint scheme. DELAWARE & HUDSON is spelled out on the carside in large letters, along with the addition of the 33″ “Bridge Line” medallion. Gone is the script “the D&H”, the Anthracite Circle, and the words “THE DELAWARE AND HUDSON RR” spelled out in 2″ letters, just below the reporting marks. Car is painted red with black car cement roof and ends. (image courtesy Norm Buckhart/Protocraft.com)

Builder’s photo of Pullman Standard PS-1, series #19400-19899, built 1952. Car is painted all red with black ends and sports the 41″ “Bridge Line” medallion, new on boxcars for 1952, is the same size as the one used on the AAR Standard offset twin hoppers. This was the last series of cars delivered to the D&H with trains still being pulled by steam locomotives. All cars ordered (and delivered) from this point forward would be a part of the diesel-era.